DTF Printing Proficiency: Raise Your Textile Creations with Direct-to-Film Innovation

DTF Printing Proficiency: Raise Your Textile Creations with Direct-to-Film Innovation

Blog Article

Ultimate Guide to DTF Printing Techniques for Sensational Fabric Styles

Beginning on the journey of grasping DTF printing strategies can open up a globe of opportunities for developing visually captivating textile designs. As the textile market proceeds to advance, remaining ahead of the curve with ingenious printing approaches is essential. In this guide, we will discover the detailed information of DTF printing, from grasping the fundamental essentials to unraveling advanced color strategies that can raise your designs to brand-new heights. Keep tuned as we look into the nuances of choosing the best materials, improving the printing procedure, and getting over usual obstacles to accomplish magnificent outcomes.

Recognizing DTF Printing Fundamentals

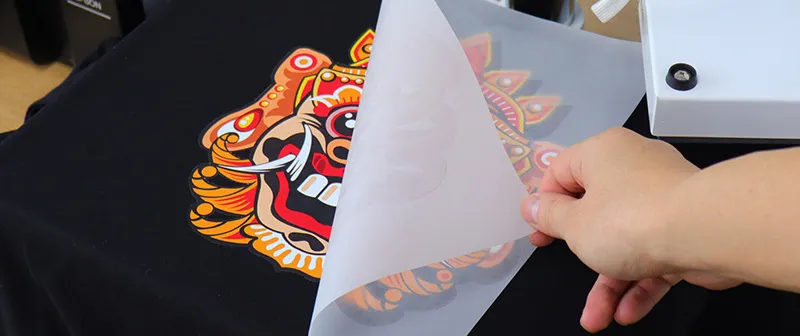

DTF printing, a process that involves moving styles from a special movie to textiles making use of warmth and stress, forms the structure of textile printing methods. This innovative method enables for top quality, lively styles to be perfectly moved onto different textiles with precision and detail. The primary step in DTF printing involves producing or picking a layout that will be published onto the textile. This style is then printed onto a special film making use of a DTF printer, which utilizes specific dyes or pigments to guarantee color accuracy and resilience.

The last result is a magnificent, lasting textile design that is washable, flexible, and resistant to fading. Generally, recognizing the essentials of DTF printing is crucial for understanding this modern-day fabric printing strategy.

Picking the Right Fabric Products

Having actually established the fundamental principles of DTF printing strategies for fabric designs, the next critical factor to consider exists in choosing the suitable textile materials to match this ingenious procedure effectively. In addition, the stretchability of these products can fit the warm transfer process included in DTF printing without distorting the style. By picking the best fabric materials, designers can take full advantage of the possibility of DTF printing to create lasting and magnificent fabric designs.

Grasping the Printing Refine

To excel in DTF printing techniques for fabric designs, understanding the printing procedure is necessary for accomplishing consistent and high-quality results. The temperature level, pressure, and period of warm application must be very carefully managed to ensure proper bond of the design to the fabric. By sharpening each of these steps in the printing procedure, designers can continually create sturdy and spectacular textile styles with DTF printing methods.

Enhancing Designs With Color Strategies

Moreover, try out shade slopes can bring a feeling of activity and fluidness to the layout. By mixing shades flawlessly, a slope result useful link can be attained, including a modern-day and vibrant touch to the textile design. Additionally, utilizing color obstructing methods can produce strong and striking visuals by juxtaposing various strong shades in distinctive areas of the style.

In addition, integrating metallic or neon colors can give a one-of-a-kind and distinctive element to the fabric style, making it stand apart and exhibit a feeling of vibrancy. When tactically used, these color strategies can raise the overall visual allure of textile designs, making them extra fascinating and memorable.

Troubleshooting Common DTF Printing Issues

After discovering different color methods to enhance fabric designs, it is necessary to address usual DTF printing issues that might arise throughout the production procedure. One common concern is poor bond, which can result from improper healing temperature levels or times. To resolve this issue, make certain that the see post curing setups are accurate and that the glue utilized appropriates for the details fabric being published on. An additional frequent challenge is shade variances, where shades may appear in different ways than expected. This can be triggered by inaccurate shade profiles or settings in the printing software application. To tackle this, ascertain the color setups and accounts to ensure they match the designated style. In addition, problems with image clarity and sharpness can happen because of low-resolution photos or improper over here printing methods. To address this, always use high-grade images and change the printing setups for optimum quality. By knowing these common issues and applying the necessary troubleshooting steps, you can enhance the overall high quality of your DTF published fabric layouts.

Verdict

To conclude, understanding DTF printing methods is important for developing sensational textile designs. By recognizing the essentials of DTF printing, picking the appropriate products, and enhancing designs with shade methods, one can achieve impressive outcomes. It is crucial to fix common concerns that may occur during the printing procedure to guarantee an effective result. With practice and attention to detail, one can develop unique and lovely fabric styles using DTF printing strategies.

DTF printing, a procedure that includes moving designs from a special movie to fabrics utilizing warm and pressure, develops the structure of fabric printing techniques.Having actually established the fundamental principles of DTF printing methods for fabric layouts, the next crucial factor to consider lies in choosing the ideal fabric materials to match this ingenious procedure efficiently. By choosing the appropriate fabric materials, designers can take full advantage of the possibility of DTF printing to create durable and sensational textile designs.

To excel in DTF printing methods for textile styles, mastering the printing process is crucial for achieving high-grade and regular results. DTF Printing. By developing each of these steps in the printing process, designers can regularly produce stunning and resilient textile designs with DTF printing techniques

Report this page